Post drivers—also known as post pounders, post knockers, and fence post hammers—are indispensable tools in construction and fencing, used to drive posts deep into the ground efficiently and securely. Over time, these tools have evolved, offering different powered options that cater to varying project needs. Whether you’re working on agricultural fencing, residential projects, or large-scale commercial installations, choosing the right post driver can make a significant impact. This guide explains how different types of post drivers work, including manual, pneumatic, gas-powered, and battery-powered post driver options.

What Is a Post Driver?

A post driver is a tool specifically designed to drive fence posts, signposts, or other stakes into the ground. It delivers powerful, uniform force, ensuring posts are driven deeply and securely with minimal risk of misalignment or damage. This precision is crucial for creating stable, durable structures capable of withstanding environmental elements. The main types of post drivers are:

- Manual Post Drivers: Operate using human power and are highly effective for smaller tasks.

- Pneumatic Post Drivers: Use compressed air to deliver consistent, powerful force, ideal for large-scale projects.

- Gas-Powered Post Drivers: Utilize combustion motors for portability and powerful performance.

- Battery-Powered Post Drivers: Combine portability with convenience and environmentally friendly operation, making them a popular choice for many users.

How Do Post Drivers Work?

Despite their differences in power sources and designs, all post drivers function by applying consistent downward force to drive posts deep into the ground. Here’s how each type works:

Manual Post Drivers: Simple and Effective

Manual post drivers are a straightforward solution for driving posts using human power:

- Design and Operation: Manual drivers consist of a heavy, hollow cylinder with one end closed. The post fits inside the open end, and the user lifts and drops the driver over the post. The weight of the driver, combined with gravity, generates the necessary force.

- Precision Strikes: The cylindrical design ensures consistent, centered strikes, transferring energy efficiently to the post.

- Cost-Effective: Manual drivers are budget-friendly, require no external power source, and are ideal for smaller or less frequent tasks.

Pneumatic Post Drivers: Air-Powered Efficiency

Pneumatic post drivers harness the power of compressed air to deliver powerful strikes:

- Air Pressure Mechanism: An external air compressor supplies pressurized air to lift the driver. When released, the driver delivers a forceful downward strike on the post.

- High Impact Force: Pneumatic drivers are known for their strength and are often used on job sites where heavy-duty performance is needed.

- Bulky Setup: While powerful, pneumatic drivers require an air compressor, making them less portable and suitable for remote locations.

Gas-Powered Post Drivers: Power and Portability

Gas-powered post drivers offer a blend of portability and impressive performance:

- Combustion Engine: These drivers utilize a small combustion engine to generate rapid tapping motions, similar to a jackhammer. This motion drives posts deep into the ground quickly and effectively.

- Versatile and Portable: Gas-powered models don’t require external power sources, making them suitable for various terrains and remote locations.

- Different Sizes Available: Common sizes include 35cc and 50cc models, offering flexibility for different post sizes and soil conditions.

Battery-Powered Post Drivers: Convenient and Eco-Friendly

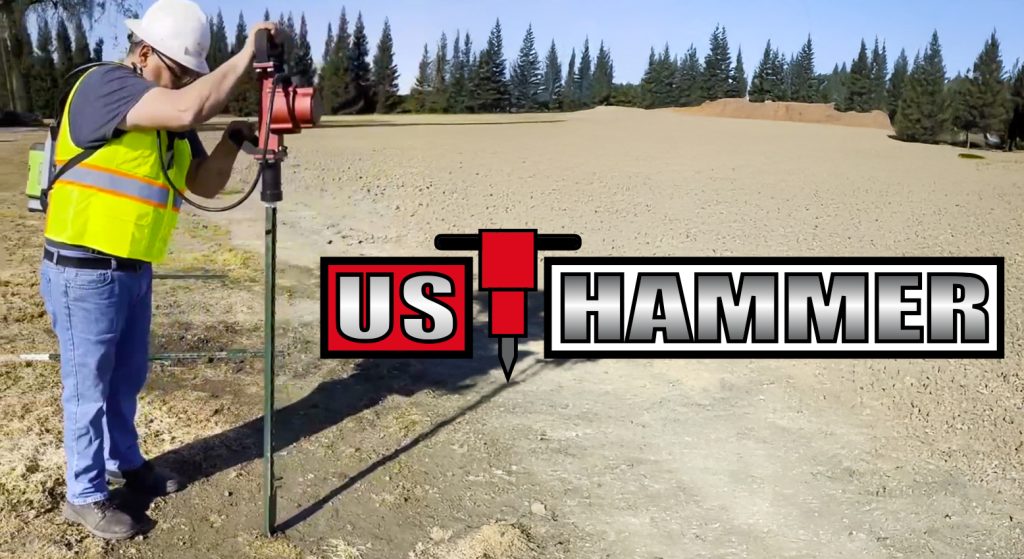

Battery-powered post drivers like the BPD-50 Battery Powered Post Driver from US Hammer have gained popularity due to their convenience, eco-friendliness, and ease of use:

- Rechargeable Lithium-Ion Batteries: These drivers are powered by high-capacity rechargeable batteries, providing consistent force without the need for cords, fuel, or air compressors.

- Quiet and Emission-Free: Battery-powered models are quieter and produce no emissions, making them suitable for residential areas and environmentally conscious projects.

- Lightweight and Easy to Handle: Typically lighter than gas-powered models, battery-powered drivers reduce operator fatigue, making them a great option for long projects.

- Limited Runtime: Depending on battery capacity, runtime may be limited, but spare batteries can mitigate downtime and keep projects moving smoothly.

Which Post Driver Is Right for Your Job?

Choosing the right post driver depends on the scale of your project, the type of terrain, and your personal preferences:

- Manual Post Drivers: Ideal for small-scale projects and budget-conscious users who don’t mind physical labor.

- Pneumatic Post Drivers: Best for job sites with access to an air compressor and where high power is needed for large projects.

- Gas-Powered Post Drivers: Suitable for heavy-duty projects that require portability and consistent power in remote locations.

- Battery-Powered Post Drivers: Great for projects that need portability, quiet operation, and an environmentally friendly approach.

Final Considerations

When selecting a post driver, evaluate the size and scope of your project, soil conditions, and power requirements. Manual drivers are effective for straightforward tasks, but they can be physically demanding. Pneumatic drivers offer unparalleled power but require a more complex setup. Gas-powered models provide robust performance with mobility, while battery-powered drivers deliver convenience, low noise, and eco-friendliness.

Whichever type you choose, take a moment to appreciate how these tools have evolved to make post installation faster, more precise, and less physically demanding. From manual to high-tech battery-powered models, post drivers have revolutionized fencing and construction projects, driving progress every step of the way.